Product features:

Automatic clay brick stacking machine is divided into three lifting methods: servo lifting, hydraulic lifting and mechanical lifting. The machine adopts advanced servo control system, which has high running precision, accurate positioning and stable working. The brick stacking machine has the functions of automatically clamping, transporting and releasing stacks. The palletizing form of the brick can be designed according to the requirements of the user, which is suitable for the use of various tunnel kilns.

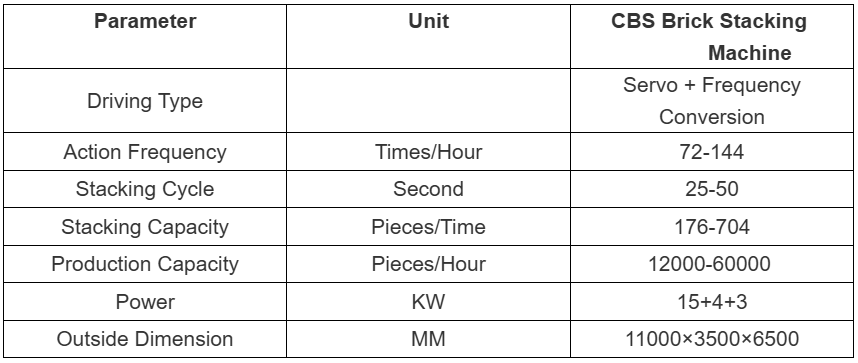

Technical parameters:

Detail Feaures

1. Efficient automation

Automatic stacking: The intelligent stacking function automatically puts the brick neatly, reducing manual intervention.

High-speed operation: The operation speed is fast, which greatly improves the production efficiency.

2. Stable and reliable

Durable design: The use of high-quality materials and construction to ensure long-term stable operation.

Fault self-diagnosis: With the self-diagnosis function, it can discover and prompt faults in time.

3. Energy saving and environmental protection

Low energy consumption: Optimized design to reduce energy consumption and save production costs.

Waste reduction: Precise placement reduces brick breakage and reduces scrap rates.

4. Intelligent control

Man-machine interface: equipped with touch screen, easy to operate.

5. Security

Multiple protection: With multiple security protection measures to ensure the safety of operation.

Emergency shutdown: Quick shutdown in case of emergency to prevent accidents.

6. Data management

Production data recording: Automatic recording of production data for easy analysis and optimization.

7. Easy maintenance

Modular design: Modular structure facilitates maintenance and replacement of parts.

Maintenance reminder: The system automatically reminds maintenance to reduce unplanned downtime.

8. Cost-effectiveness

Reduce labor costs: Automation reduces reliance on labor and reduces labor costs.

Increase production: Efficient operation increases production and increases corporate revenue.

Machine Detail Explain:

Above is the Lifting mechanism

The lifting mechanism of the clay brick stacking machine adopts servo drive technology, positioning accuracy, stable operation, flexible action, high precision, to ensure the reliability of long-term high frequency operation.

Above machine is Brick Arranging Machine - use to transfer bricks

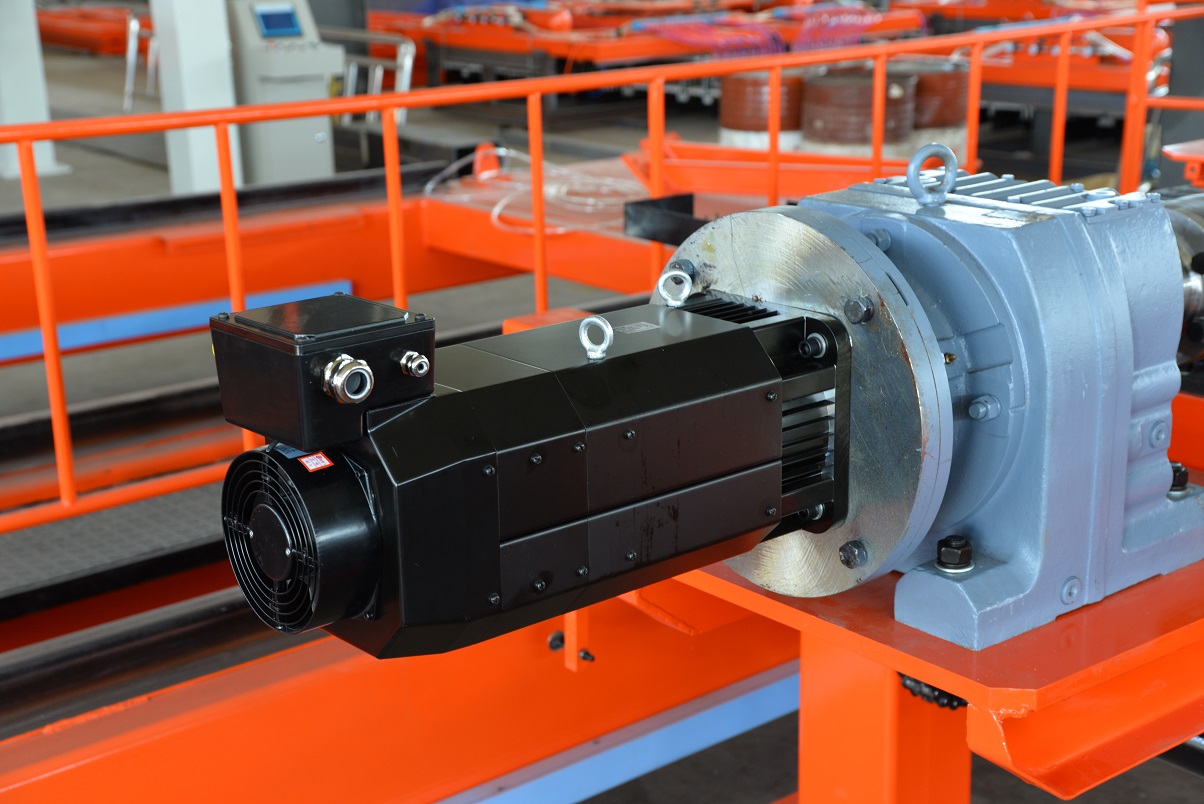

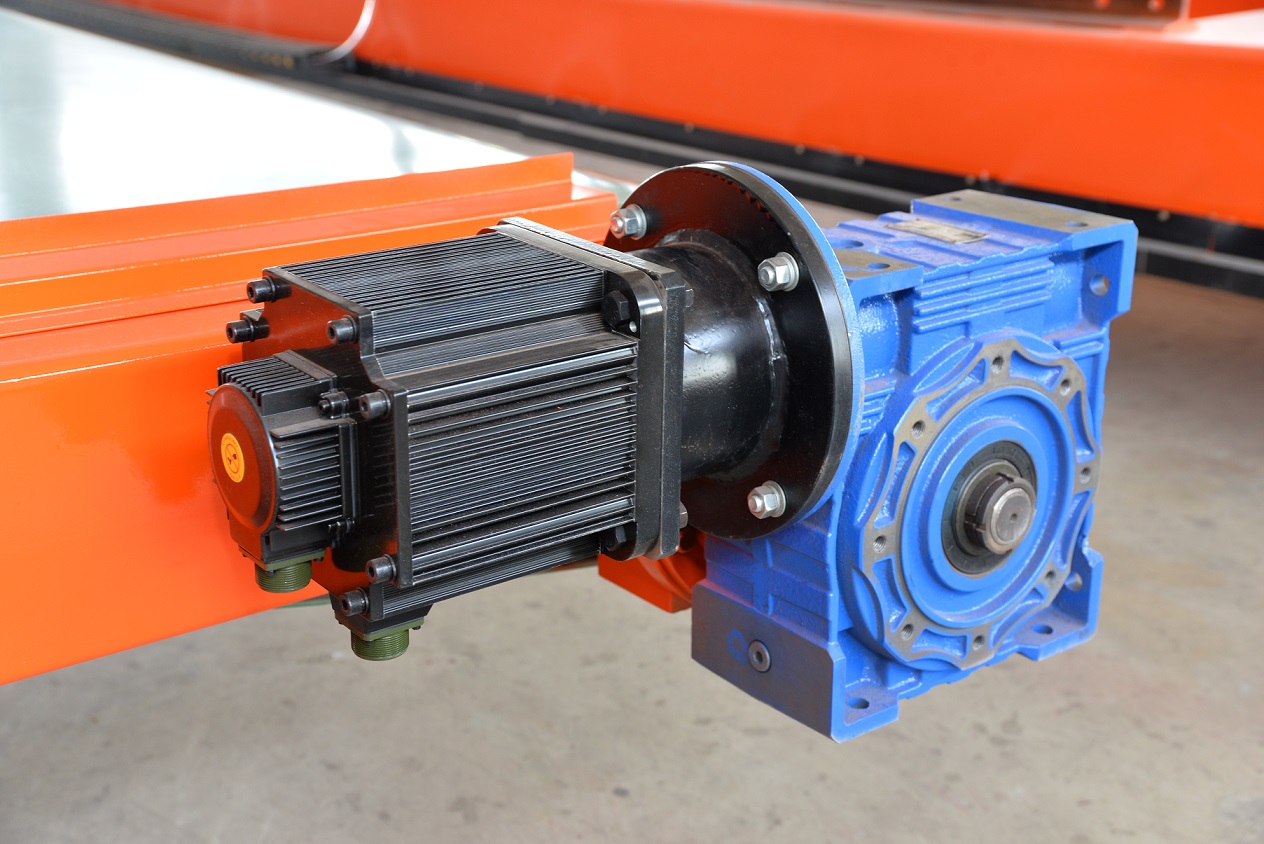

Motor for Brick Arranging Maching

Brick arranging machine equipped with servo motor, high precision, smooth running.

Above is Guide Rope

The guide rope mechanism fixes the path of the wire rope through the wire board, combines with the rotating pulley to reduce friction and the pull-out design is easy to eliminate winding problem. This guide rope mechanism also reduce the wearing of the wire rope and the wheel groove and extend the service life

Above is the brick spliting system

The brick splitting system adopts the mechanical structure design of linear guide rail high hardness optical shaft. The main technical features are as follows:

Linear guide rail: high-precision ball linear guide rail is used to realize the smooth sliding of the dividing mechanism along the preset track, and the repeated positioning accuracy can reach ±0.1mm2.

• High hardness optical shaft: The 40Cr alloy steel optical shaft with chrome plated surface, Rockwell hardness ≥HRC58, combined with self-lubricating copper sleeve bearing, effectively reduce friction loss.

Above is the Main Frame and columns

500x400 square pipe profiles are used to enhance the rigidity of the overall structure, without deformation in use, and are durable.

leave a comment