Product features:

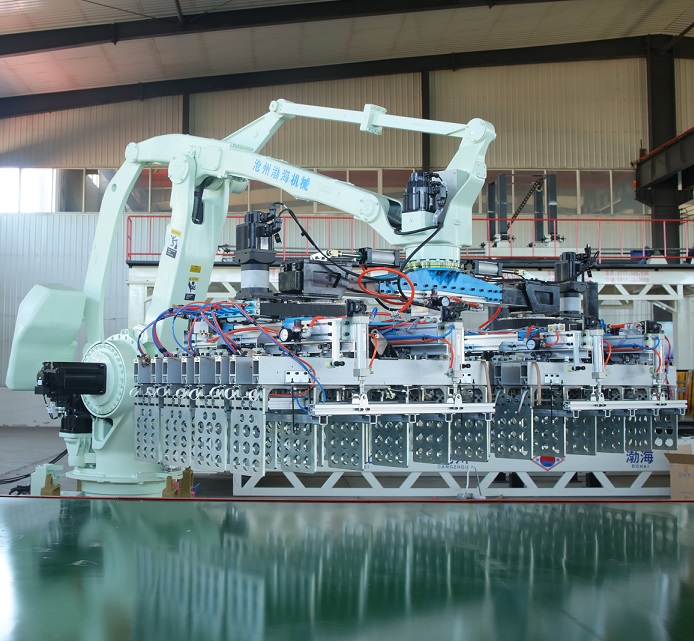

The automatic cutting, stacking and turning system of industrial robots can flexibly design the fixture according to different stacking forms and brick types. This system is electrically driven based on AC servo, and the working process is automatically controlled by PLC.

The automatic cutting, stacking and turning system of industrial robots creates an artificial intelligence-based production for bricks and tiles, which is an inevitable development trend for brick machine manufacturers. Under the new situation, Bohai Machinery applies the robot brick blank stacking integration system and hard plastic extrusion molding technology to the brick and tile industry, achieving intelligent production. It can save you a large amount of human resources, increase production output and economic benefits.

Other Features:

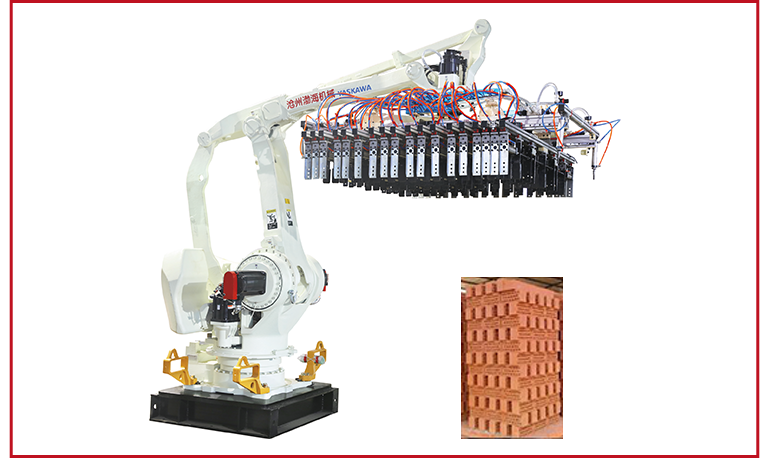

The industrial clay brick robot stacking machine adopts the four-axis robot of the imported Yaskawa brand, demonstrating core advantages of high precision, high efficiency, and high stability in the scenario of brick blank palletizing.

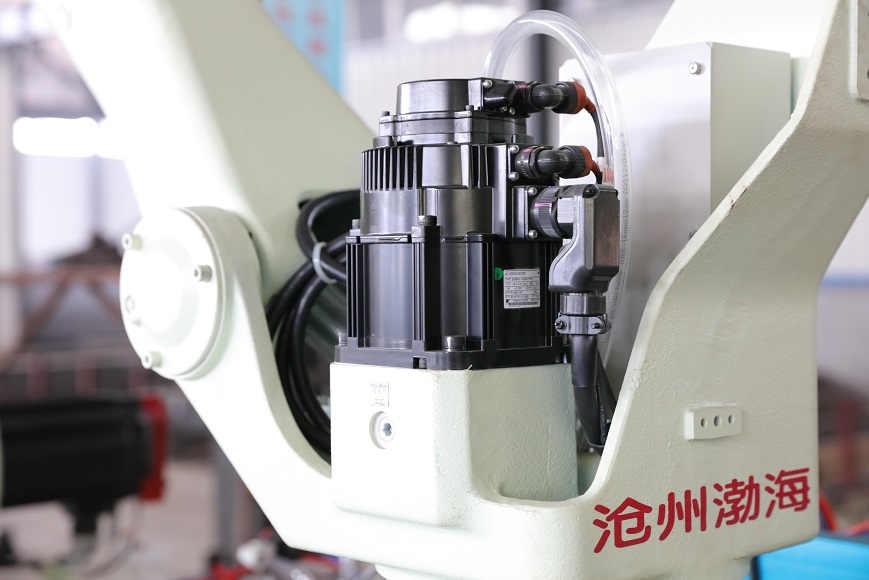

1. High-precision motion control

a Repeated positioning accuracy: -0.05mm, ensuring that the alignment error between layers of brick blanks is ≤1mm to avoid the risk of stack collapse.

b Servo drive technology: Using the 7 series servo motor, with a response time ≤5ms, adapting to high-speed start and stop (cycle ≤8 seconds per layer).

2. Four-axis degree-of-freedom design

a Motion range:

b Horizontal joints (J1/J2 axes): covering a radius of 2.5-3.2m, suitable for parallel palletizing of multiple kiln cars;

c Vertical lifting (J3 axis): with a stroke of 1.2-1.8m, supporting flexible adjustment of the layer height;

d End rotation (J4 axis): -180 degree rotation, enabling interlaced palletizing of brick blanks in the shapes of the Chinese character “工”, “井”.

e Simplified structure: Compared with the six-axis robot, the four-axis design reduces redundant joints, reducing the failure rate by 30% and lowering the maintenance cost.

3. Adaptation of load capacity

a Standard load is 500-800kg, capable of grasping 200-360 standard bricks at a time, with a maximum palletizing speed of 20,000 bricks per hour.

4. Special gripper design

a Special steel plate set: For smooth brick surfaces, it can withstand a temperature of up to 150°C and supports quick adsorption and release;

b Claw-type gripper: Suitable for special-shaped bricks (such as perforated bricks), with an adjustable clamping force of 10-200N, preventing slipping and breaking;

c Modular quick change: Supports the switching between the suction cup and the claw within 10 seconds, suitable for multi-variety production.

5. Intelligent control system

a PLC Yaskawa controller: Supports offline programming and has multiple preset palletizing templates (number of layers, arrangement angle);

6. Safety protection

a Double-circuit brake: Locks the joints instantly when power is cut off to prevent the gripper from falling.

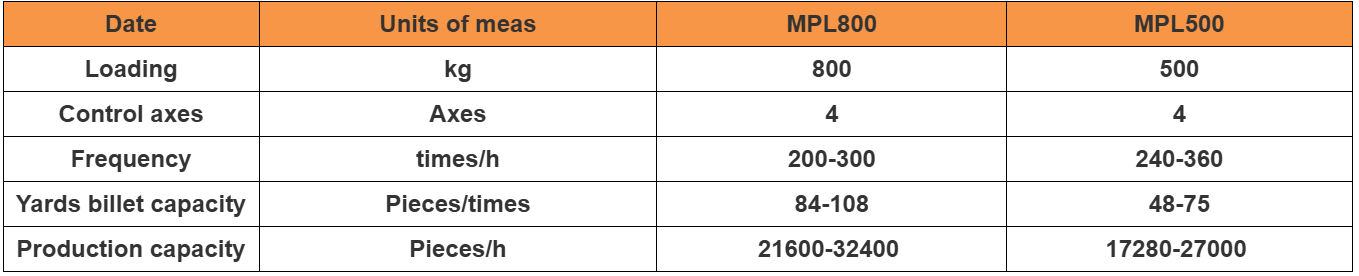

Technical parameters:

The example of the Clay Brick Robot Stacking System:

leave a comment