Product features:

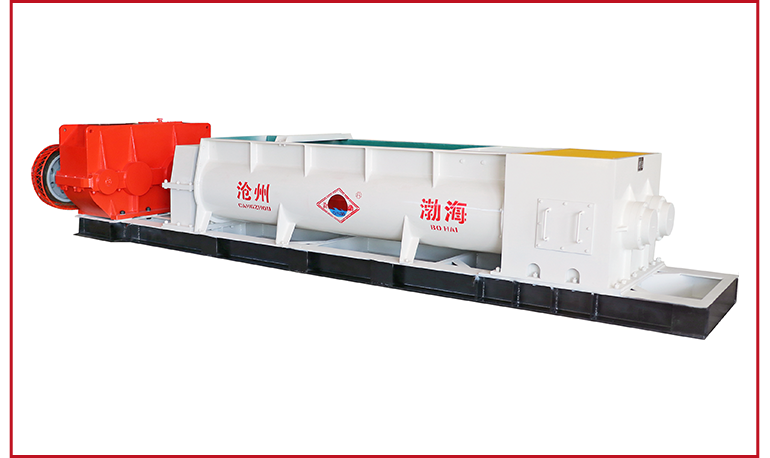

This machine is suitable for raw materials such as clay, coal gangue, shale, fly ash; To add water to mixing, mixing raw materials, can fully improve the plasticity of materials.

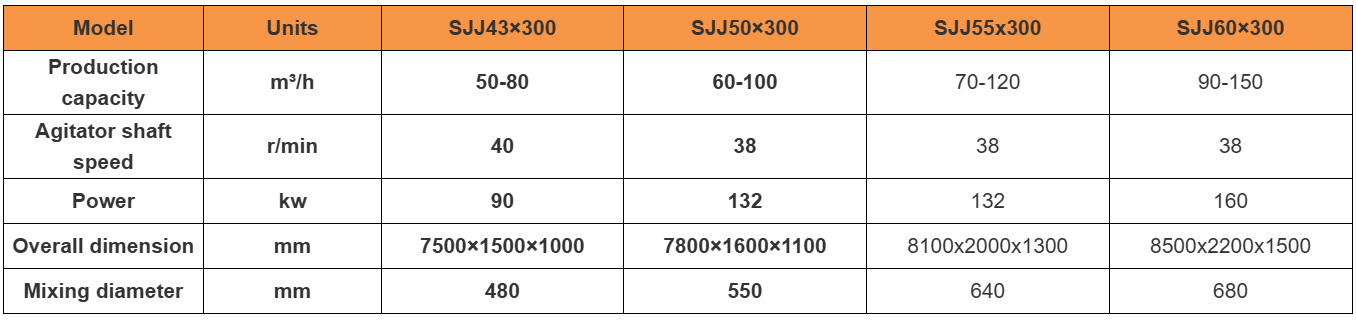

The technical parameters:

Detail Explain:

The rear end adopts fine twisting blades with a small pitch and high rotational speed. By extruding with high pressure to expel air, it can significantly improve the compactness and plasticity of hard raw materials such as shale gangue. At the same time, it reduces equipment wear and tear, making it suitable for the production of high-end products such as high-strength permeable bricks and sintered insulating bricks.

Adoption of composite blades

A structure of “metal base ceramic lining board” is adopted. The base is made of Q345 steel for support, and ceramic sheets with a thickness of 3 - 5 mm are bonded to the surface to balance strength and wear - resistance.

Streamlined blade edge

The blade edge is designed with a 30° - 45° bevel to reduce cutting resistance and prevent hard particles from getting stuck in the gaps.

Modular quick - disassembly

The blades are fixed by bolts. If a single blade is damaged, it can be quickly replaced without disassembling the entire mixing shaft.

The application of ceramic mixing blades is particularly suitable for harsh working conditions such as processing gangue and recycled aggregates from construction waste. Compared with traditional processes, these mixing blades are not only wear - resistant but also save labor and maintenance costs.

leave a comment