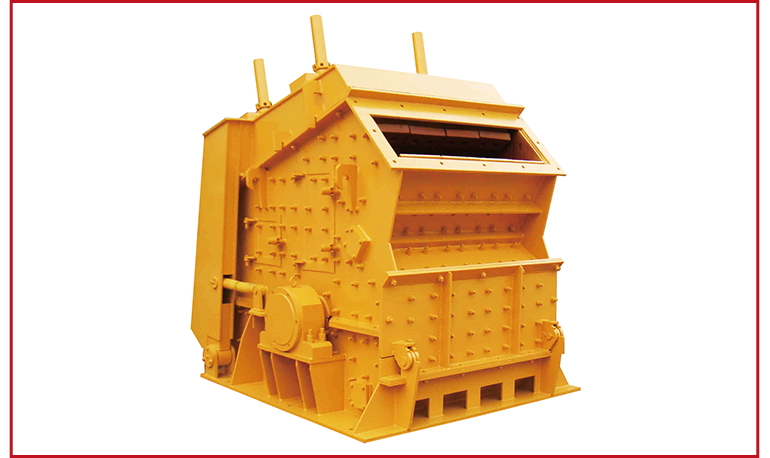

As an efficient crushing equipment, the core function of the hammer crusher lies in the particle size conversion operation of medium-hard and brittle materials. The typical application scenarios are concentrated on the crushing and processing of minerals such as shale and coal gangue. Through the mechanism of impact crushing, the raw materials are cleaved into powder and granular materials that meet the technological requirements. In the field of new building material production, relying on its excellent raw material pretreatment ability, this equipment has become the core unit for preparing aggregates in the brick and tile manufacturing industry. It shows significant advantages especially in the process of adjusting the gradation of raw materials for building blocks.

Product features:

This series of crusher can handle materials less than 500 mm long, its compressive strength up to 147-245Mpa, has the advantages of large crushing ratio, cube particles after crushing materials, suitable for crushing hard materials, with the advantages of large production capacity and small particle size.

Product Detail:

Name: Liner Plate

Innovation in Material System

• Bimetallic Composite Process

The base body adopts modified high-manganese steel, and a 3mm-thick high-tungsten carbide layer is compounded on the impact surface, achieving the coordination of a surface hardness of 62-65HRC and an impact toughness of the base body AKv≥80J.

• Heat Treatment Optimization

Two water quenching and tempering treatments (quenching at 1050°C tempering at 250°C) are carried out to eliminate the casting stress and at the same time increase the work hardening rate to HB450 .

Breakthrough in Structural Design

• Crushing Chamber with Gradually Changing Curvature

Three-dimensional parametric design:

• The curvature radius of the feeding section R = 800mm (ensuring that large pieces of materials can be bitten in)

• The curvature gradient change rate of the crushing section is 1:12 (enhancing the lamination crushing effect of the materials)

Surface Strengthening Technology

• Micro-texture for Drag Reduction

An array of rhombic pits is processed on the surface through micro-milling, reducing the friction coefficient by 23% and decreasing the adhesion of clay.

.

.

Name: Liner Plate

Innovation in Material System

• Bimetallic Composite Process

The base body adopts modified high-manganese steel, and a 3mm-thick high-tungsten carbide layer is compounded on the impact surface, achieving the coordination of a surface hardness of 62-65HRC and an impact toughness of the base body AKv≥80J.

• Heat Treatment Optimization

Two water quenching and tempering treatments (quenching at 1050°C tempering at 250°C) are carried out to eliminate the casting stress and at the same time increase the work hardening rate to HB450 .

Breakthrough in Structural Design

• Crushing Chamber with Gradually Changing Curvature

Three-dimensional parametric design:

• The curvature radius of the feeding section R = 800mm (ensuring that large pieces of materials can be bitten in)

• The curvature gradient change rate of the crushing section is 1:12 (enhancing the lamination crushing effect of the materials)

Surface Strengthening Technology

• Micro-texture for Drag Reduction

An array of rhombic pits is processed on the surface through micro-milling, reducing the friction coefficient by 23% and decreasing the adhesion of clay.

Name: Hammer Head

Gradient Composite Casting Technology

Using high-chromium alloy as the base body and adding cemented carbide particles at the hammer end to form a gradient structure with a surface hardness of ≥62HRC and a base body toughness of ≥35J/cm², achieving the coordinated optimization of impact resistance and wear resistance.

Dynamic Balance Design

The counterweight of the hammer head is optimized through finite element analysis, and the weight tolerance of a single hammer head is controlled within ±0.15kg to ensure that the dynamic balance accuracy of the rotor assembly reaches grade G6.3 and the vibration value is ≤4.5mm/s.

Innovation in Reversible Structure

The bimetallic composite hammer head is provided with 4 effective striking edges. It can be turned 180° for use through the hydraulic quick-change system, effectively extending the service life by 30%.

leave a comment