Product features:

The box-type feeder has the function of homogenization of material and constant sending material.it also can crush the big material during the transportaion.

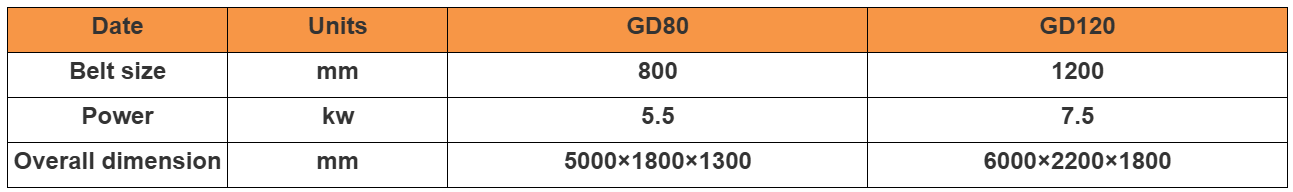

Technical parameters:

Product Description:

As the core equipment for raw material pretreatment, the box-type feeder undertakes the dual functions of uniform and quantitative conveying and primary screening of materials such as shale and coal gangue. Its operation stability directly affects the efficiency of the crushing system. In modern brick factories, it needs to meet the requirement of continuous feeding of 30-80t/h, and cooperate with the double-stage vacuum extruder to achieve precise control of the moisture content fluctuation within ≤±2%.

1. Power Matching

• Speed Ratio Matching: The rotation speed of the motor and the output shaft of the speed reducer are precisely designed..

• Torque Redundancy: The rated torque of the speed reducer is 1.8 times the design requirement to ensure the instantaneous overload capacity when the coal gangue gets stuck.

2. Maintenance Synergy

• Synchronized Maintenance Cycle: The lubricating oil change cycle (3000h) of the speed reducer is coordinated with the maintenance cycle (5000h) of the motor bearings.

• Quick Disassembly and Assembly Design: The motor and the speed reducer adopt an elastic pin coupling (allowable radial deviation of ±0.5mm).

1.Innovation in Material System • Pipe Body Strengthening Cold-drawn seamless alloy steel pipes are adopted. • Bearing Set Optimization Double-sealed deep groove ball bearings are used, matched with lithium-based grease, and the dustproof grade is IP66.

2. Breakthrough in Structural Design • Hollow Shaft Weight Reduction Design The hollow rate of the shaft body is 40%, and a spiral diversion groove is configured. While reducing the overall weight by 28%, the flexural strength is maintained at ≥750MPa. 3. Upgrade of the Sealing System • Five-layer Labyrinth Seal A non-contact rubber composite seal is adopted, and the dust intrusion amount is less than 0.01g per thousand hours.

• Cover layer: Composed of rubber and silicon carbide particles, with a wear resistance index ≤ 90mm³ and tear resistance ≥ 25kN/m.

• Reinforcement layer: Polyester canvas (EP400×6 layers) longitudinal steel wire ropes (Φ4mm), with a longitudinal tensile strength ≥ 2000N/mm.

• Lower cover layer: Rubber graphene coating (with a thickness of 2mm), and the conductive resistance ≤ 3×10⁸Ω.

This conveyor belt solution, through the composite reinforcement structure technology, can meet the stringent requirement of the box-type feeder in brick factories for continuous operation of 8000 hours per year.

leave a comment