It is specially designed for bigger main machine, type 55, 60, 70, 75 and above, high capacity and fully hard mould production line. With strong pushing power and high strength structure, it is suitable for making standard, multihole and large block bricks with shale and coal gangue.

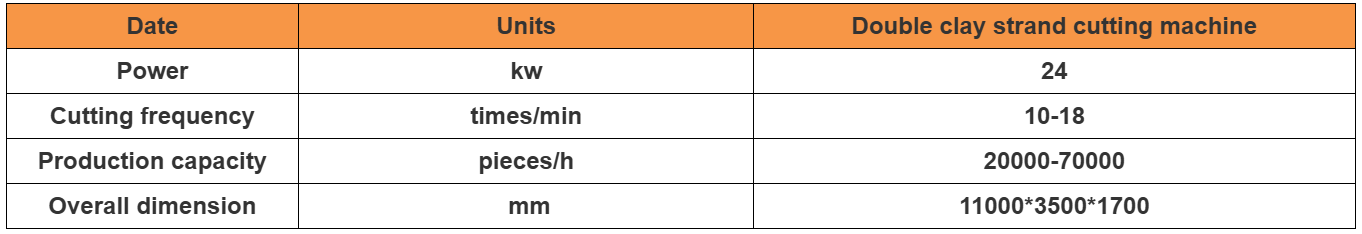

Cutting frequency<=20 times/min, cutting height up to 260mm, cutting clay strand length: 1750-2500mm

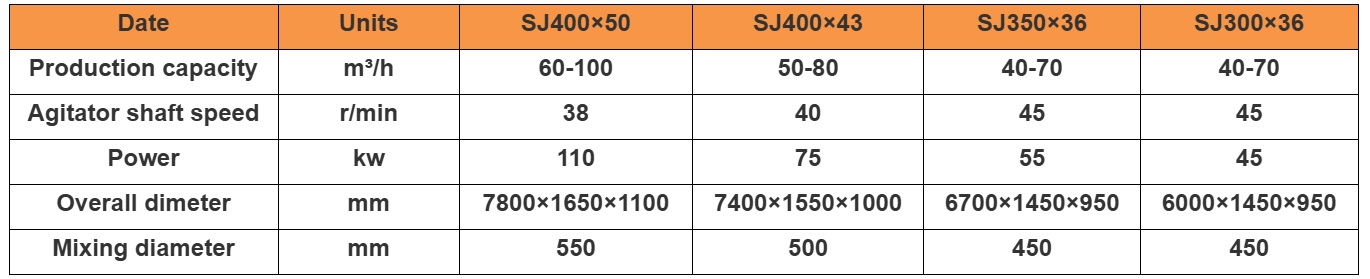

Technical parameters:

Detail Explain:

There are two sets of wire cutting units, once the operating set of wire cutting unit steel wire broken, another spare unit could be put into position easily. This type of units could avoid the brick blank extruder stop working.

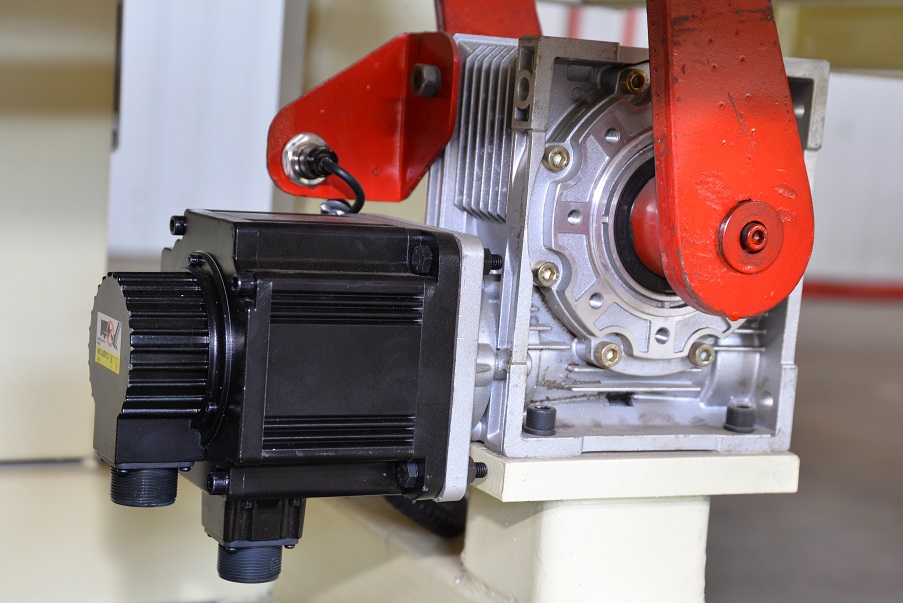

1. Prolong the motor's service life

Reduce the impact of starting current: When the motor starts, the current can reach 5 - 7 times the rated value. Frequent starting and stopping can easily lead to overheating of the windings and aging of the insulation.

2. Reduce energy consumption

Low free load energy consumption: When the clutch is disengaged, the free load power of the motor is only 10% - 20% of the rated power.

3. Improve equipment reliability

Reduce mechanical impact: Traditional direct starting and stopping can easily cause instantaneous overload of transmission components such as gears and belts. Long - term operation can lead to fatigue and fracture.

Precise braking protection: The braking device prevents inertial slippage, ensures consistent stopping positions, and avoids cutting misalignment or tool collisions.

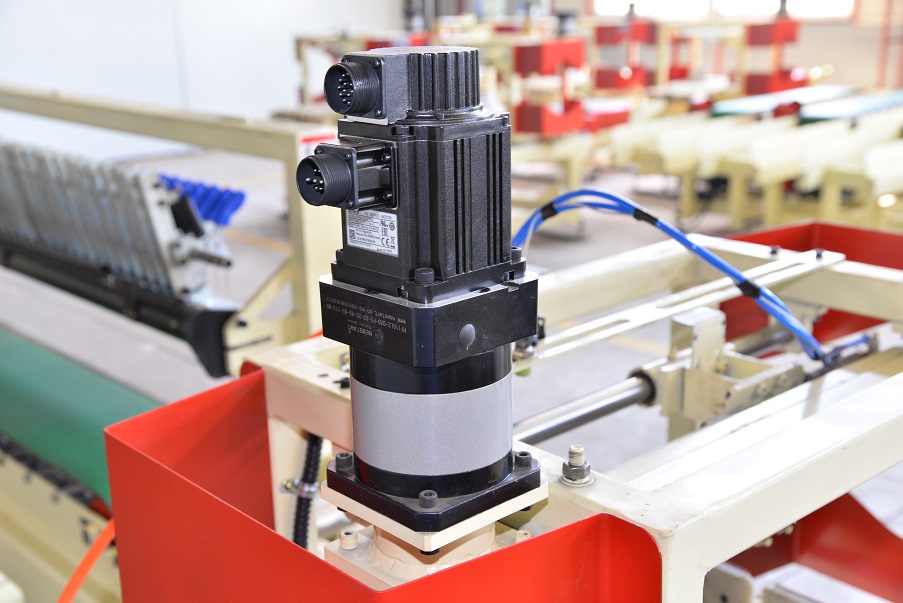

4. Improve production efficiency

Quick response: The switching time between the pneumatic clutch and the brake is short, which is suitable for high - speed continuous production.

Seamless connection: The continuous operation of the motor eliminates the time for restarting and accelerating, shortening the cycle interval.

The blank cutting machine is equipped with an automatic braking device and a pneumatic clutch system. Through the mode of 'continuous motor operation on - demand power transmission', it fundamentally solves the problems of motor and mechanical wear caused by frequent starting and stopping.

The servo system ensures strict synchronization of actions such as feeding and stacking, avoiding misalignment of the blanks. The linear guide rails and synchronous belts are driven by servo motors to achieve millimeter-level positioning of the blanks, and the photoelectric switches are used to correct any offsets. Thanks to its closed-loop control, multi-axis coordination, and dynamic response characteristics, the servo system can achieve high-precision cutting, flexible process adjustment, and efficient production management. It is suitable for the processing scenarios of blanks in customized brick factories.

The servo system ensures strict synchronization of actions such as feeding and stacking, avoiding misalignment of the blanks. The linear guide rails and synchronous belts are driven by servo motors to achieve millimeter-level positioning of the blanks, and the photoelectric switches are used to correct any offsets. Thanks to its closed-loop control, multi-axis coordination, and dynamic response characteristics, the servo system can achieve high-precision cutting, flexible process adjustment, and efficient production management. It is suitable for the processing scenarios of blanks in customized brick factories.

1. Corrosion and rust resistance: It prevents the surface roughness, material jamming or contamination of blanks caused by the rusting of ordinary carbon steel idlers.

2.Surface treatment: Polishing treatment reduces the adhesion of blanks and lowers the frequency of cleaning. It enhances the surface hardness and prolongs the service life under heavy - load scenarios.

3. Structural design: The seamless steel tube roller body avoids weld cracking, ensures uniform load - bearing, and is suitable for high - speed and high - load conveying.

4. Low friction coefficient: The friction coefficient between stainless steel and the nylon conveyor belt is stable, reducing the risk of slipping or deviation.

The application of stainless - steel idlers in the strip and blank cutting machine significantly improves the reliability and hygiene standards of the equipment in harsh environments through its characteristics such as corrosion resistance, high wear resistance, and easy cleaning. The cooperation between stainless - steel idlers, servo systems, and photoelectric detection further guarantees the accuracy and efficiency of blank conveying.

leave a comment