Our Two Stage Clay Brick Vacuum Extruder is a crucial part of the automatic production line. It features advanced vacuum technology and precise extrusion control, ensuring high-quality brick output. As a professional factory, we possess the capabilities to manufacture the entire production line, providing comprehensive solutions for your brick-making needs.

Product features:

The machine adopted both domestic and overseas advanced technology, low energy consumption and high yield, stable and reliable performance, convenient operation and maintenance, and use of coal gangue, shale, fly ash, industrial waste residue as raw material, it is a ideal equipment in the production of sintered brick.

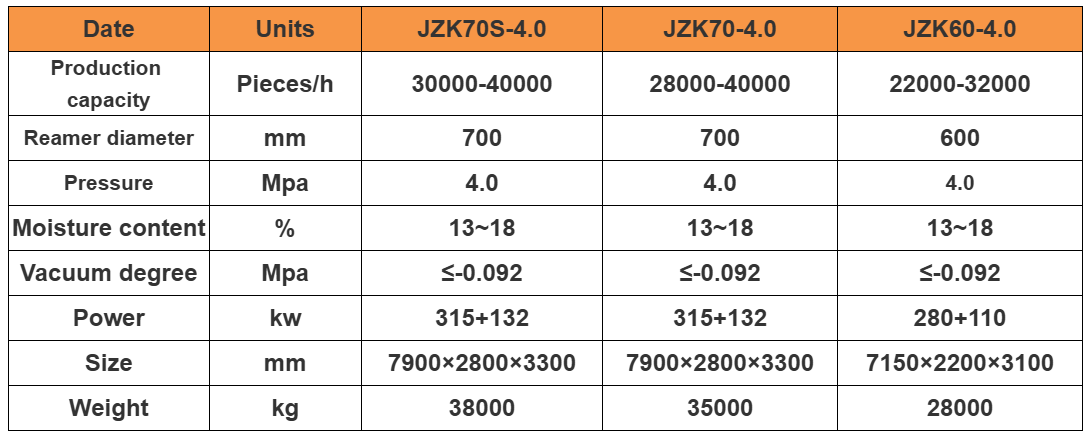

Second, the technical parameters:

Product Detail Explain:

The upper main shaft is made of 40Cr material and subjected to quenching and tempering treatment. This quenching and tempering process ensures the fatigue resistance of the main shaft body and enhances the shaft's toughness. A thick protective sleeve is added outside, which effectively protects the shaft from wear and further reduces the

This is the shaft protective sleeve

The above is the main shaft of upper stage

The lining plate is made of high-chromium alloy material, which features high hardness, wear resistance, corrosion resistance, and thermal fatigue resistance. These characteristics significantly extend the service life of the lining plate and enhance the stability of the equipment.

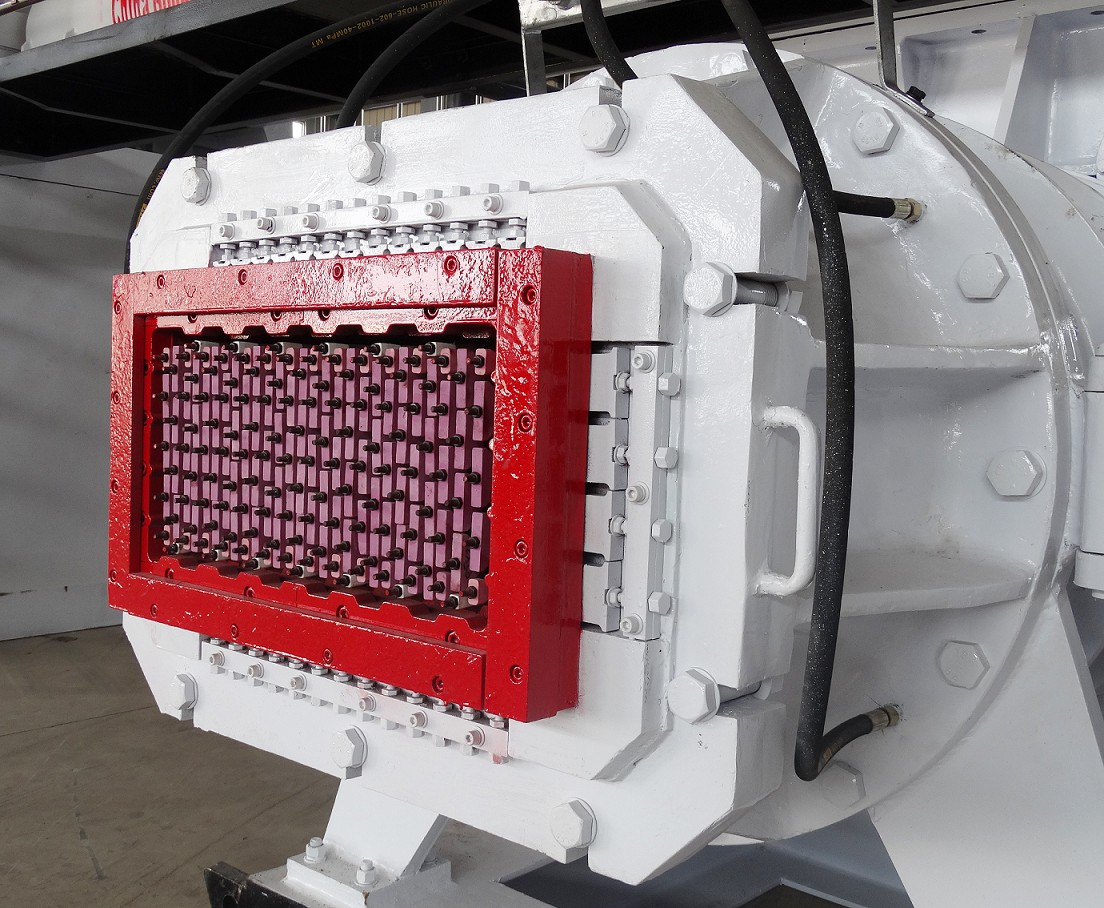

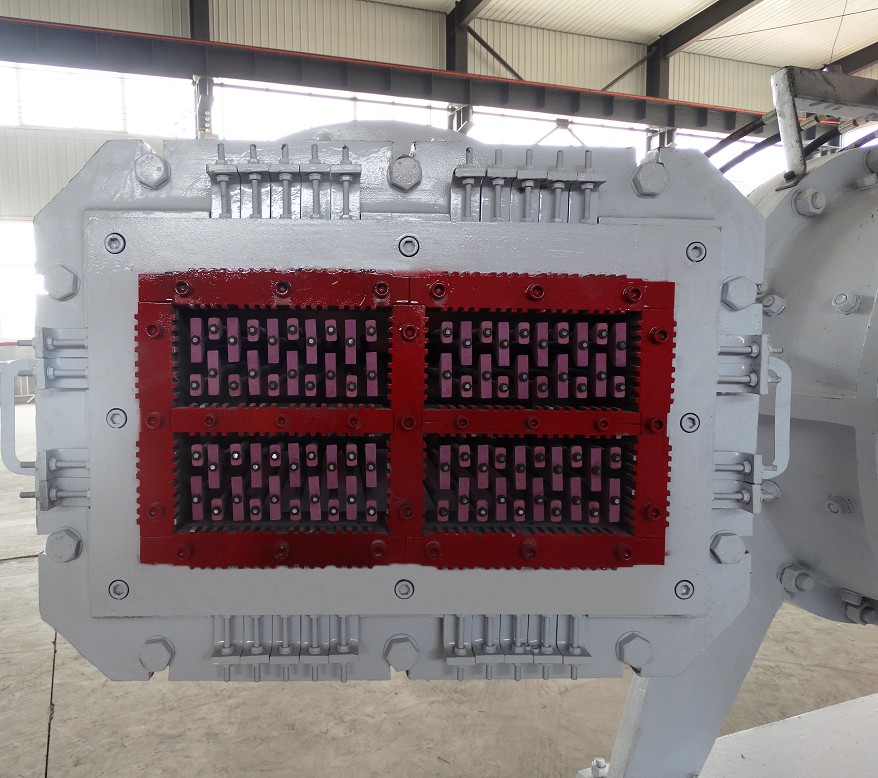

The die head is connected to the extrusion section by a flange. There's no need to disassemble the whole machine. You can quickly replace the molds with different hole patterns, enabling flexible production of various brick blanks such as standard bricks, hollow bricks, and perforated bricks.

leave a comment