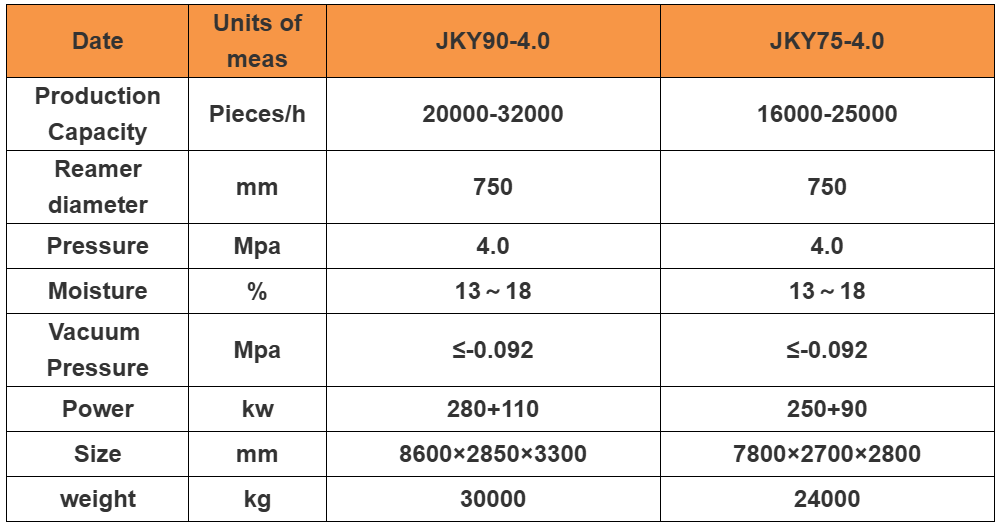

JKY90/75-4.0 Double Stage Vacuum Extruder (with Stirrer)

Product Description:

The Clay brick Double stage vacuum extruder is a high - performance machine designed for clay brick production. Its double - stage structure ensures efficient extrusion. By creating a vacuum environment, it removes air from the clay, enhancing the density and strength of the bricks. This results in high - quality bricks with excellent durability. It's widely used in the construction industry, helping to produce bricks that meet various building requirements, and improves production efficiency.

Product features:

Product Detail Descritpion:

The variable-diameter structure from the upper mixing tank to the vacuum chamber is one of its core designs. By optimizing the flow path of the raw materials and the pressure gradient, it achieves the core objectives of efficient degassing, low-energy-consumption operation and long-life maintenance. Its gradually shrinking and then expanding channel not only improves the quality of raw material processing, but also reduces the risk of material blockage, making it especially suitable for the production lines of brick factories that handle complex raw materials.

The above shows is the upper stage reducer

The single-axis ceramic mixing blade has the characteristics of super hardness, wear resistance, corrosion resistance and low adhesion, which significantly prolongs the service life of the equipment and reduces the comprehensive operation and maintenance costs. It is especially suitable for the production lines of brick factories that handle highly abrasive and corrosive raw materials.

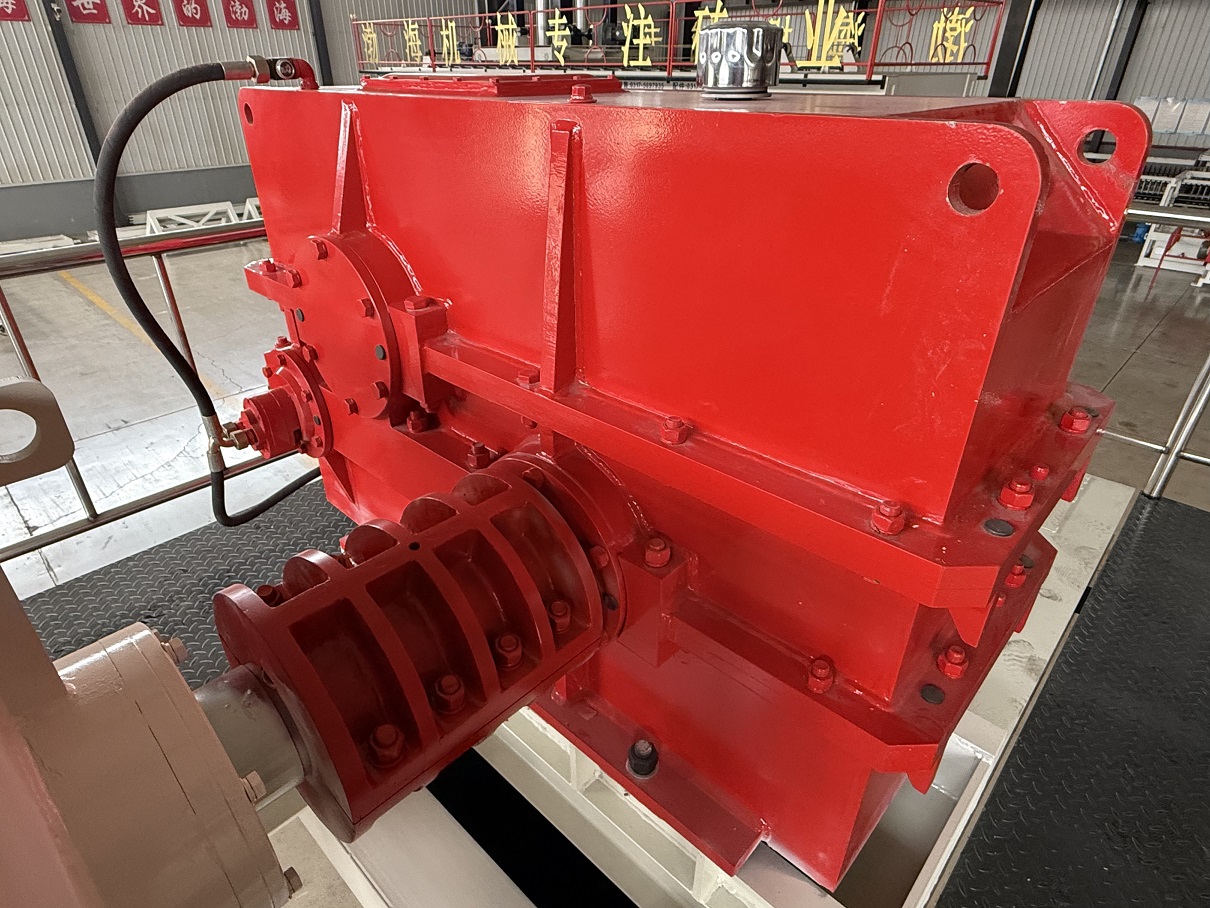

The above shows the lower stage reducer.

The inner wall of the lining plate adopts a groove-type design, which optimizes the flow path of the raw materials, reduces the eccentric wear caused by local eddy currents, and improves the wear uniformity by 30%.

The main shaft bearing seat of the double stages single-shaft extruder is integrated with the mud tank, which ensures the concentricity of the main shaft and is conducive to effective and uniform extrusion. It has a large extrusion pressure and small fluctuations. The flexible combination design of the upper and lower stages makes the mixing length of the upper and lower stages particularly long. The compression section pre-compresses the clay material, ensuring a high degree of vacuum and making the brick blank body denser. With its reasonable design and compact structure, the equipment is easy to maintain, reducing downtime and maintenance costs. The double stage single-shaft extruder not only improves production efficiency and quality but also reduces production costs through energy conservation and consumption reduction.

The upper and lower reducers adopt helical gear transmission. Compared with spur gears, the contact area is increased by 40%, and the transmission efficiency is increased to more than 98%.The high-precision meshing of hardened tooth surface gears, combined with the design of the vibration damping base, can control the noise at ≤ 75dB(A), and the service life is longer.

leave a comment