Product features:

The double clay strand and bi-directional strip and brick blank cutting machine is specially designed for large-scale main machines of models 120S, 150S and above, high-capacity and fully hard plastic production lines. It has a strong pushing force and high structural strength. It is suitable for standard bricks, perforated bricks and large building blocks made from raw materials such as shale and coal gangue.

The cutting frequency is less than or equal to 25 times per minute. The cutting height can reach up to 260 millimeters, and the length of the cut clay strand is between 1,750 and 2,500 millimeters.

Features Description of the Double-pushing Brick Blank Cutting and Strip Cutting Machine:

Bidirectional Synchronous Drive:

It adopts a symmetrical layout of dual cylinders and dual motors. The brick pushing plate achieves a bidirectional reciprocating motion within the same working cycle, eliminating the 'idle stroke waiting' time of traditional unidirectional brick pushing. The cycle time is shortened by 30% to 40%.

Example: In a standard brick production line, the brick pushing frequency is increased from 12 times per minute to 18 times per minute, and the daily production capacity is increased by 20%.

Repeat Positioning Accuracy: ±0.01mm, ensuring that the cutting size error of the brick blank is ≤0.5mm and reducing the rejection rate.

Overload Capacity: It supports a 300% instantaneous overload (lasting for 3 seconds) to cope with the fluctuation of the cutting resistance of hard raw materials.

Load Requirements for Stacking Large-sized Cut Blocks: The servo motor has a stable high torque output and there is no risk of step loss.

Energy Efficiency Grade: Meeting the IE4/IE5 standards, it saves 20% to 30% more energy compared to ordinary asynchronous motors.

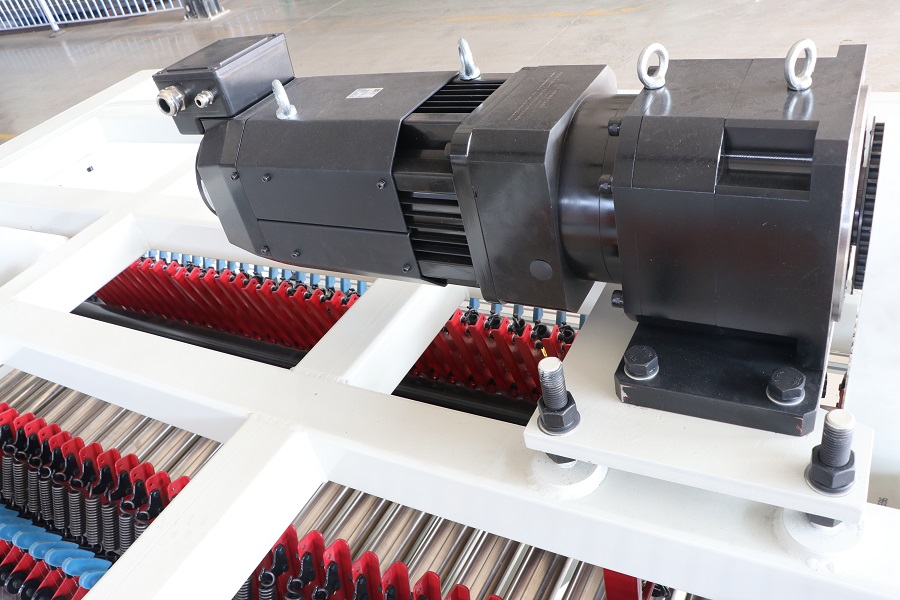

Reducer Matching: The reducer of Guomao brand is selected, which greatly increases the output torque and is suitable for high-load cutting requirements.

Through bidirectional drive, full servo intelligent control, and structural innovation, the bidirectional brick pushing technology achieves efficient, energy-saving, and stable brick blank pushing, especially suitable for high-precision block production lines, large-scale standard brick production lines, and special brick production lines. Its patented design (ZL 2021 2 0937656.1) has been verified to bring significant benefits in actual production.

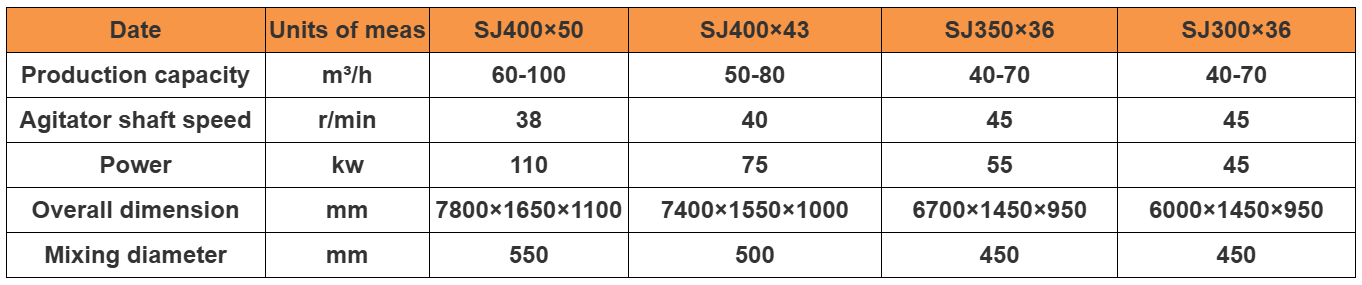

Technical parameters:

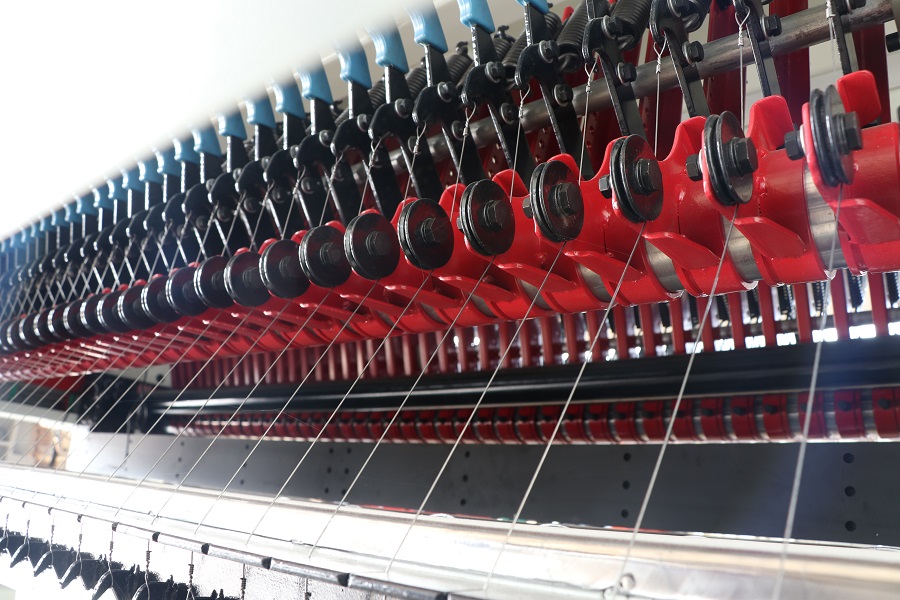

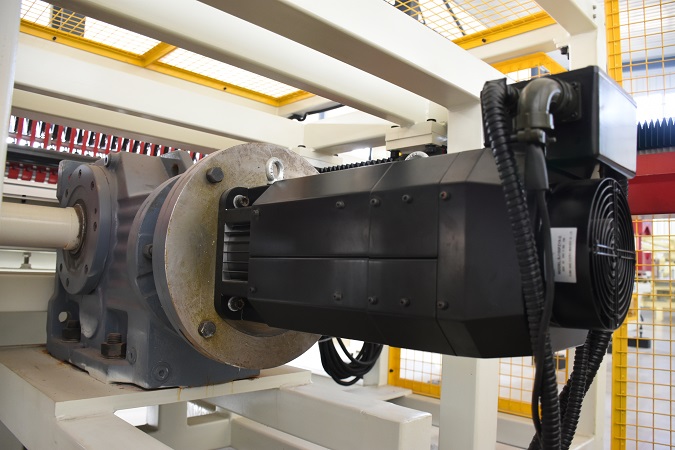

Detail Photos:

The new integrated wire-hanging device allows for flexible and convenient brick type replacement.

Position closed-loop control:

The servo motor provides real-time position feedback through the encoder to ensure the precision of the cutting blade's movement on the linear guide rail, preventing dimensional deviations in the cut brick blanks.

Instantaneous start and stop:

The servo motor has a short acceleration/deceleration time (down to milliseconds), meeting the high-speed continuous operation requirements of the brick blank cutting machine and reducing idle waiting time.

On-demand output:

The servo motor only outputs high torque during cutting operations. It consumes extremely low energy when idle or on standby, saving 20% - 40% of energy compared to traditional asynchronous motors.

Overload protection:

The servo drive continuously monitors the current. When an overload occurs, it automatically reduces the frequency or stops the motor to protect the motor and mechanical structure.

Synchronized cutting and feeding:

The servo motor works in conjunction with the feeding mechanism (such as belts and rollers) to ensure strict synchronization between the brick blank conveyance and the blade movement, preventing cutting misalignment.

The servo motor offers a high-precision, high-response, and energy-efficient core driving force for the brick blank cutting machine. It is particularly suitable for modern production lines with strict requirements for cutting quality and production efficiency. Its collaboration with components such as linear guide rails and photoelectric switches enables full-process automation from brick blank positioning, cutting to stacking, significantly reducing the reject rate and energy consumption costs. Brick blank cutting machines driven by servo motors have become key equipment for enhancing competitiveness.

The photoelectric switch is linked with the PLC. After detecting that the brick blank is in place, the cutting will be automatically started, enabling continuous production. This reduces manual intervention and improves production efficiency. If the photoelectric switch fails to detect the passage of the brick blank for a long time, it can trigger an alarm to indicate a blockage. When the position is offset and the brick blank does not reach the cutting position as expected, the equipment will automatically stop to avoid idle cutting. In the brick blank cutting machine, the photoelectric switch significantly improves the automation level and safety of production by detecting the position of the brick blank in real time, triggering automatic control, and ensuring the safety of personnel. Its application effect directly affects the operation efficiency, product quality, and maintenance cost of the brick blank cutting machine.

The application of linear guide rails combined with rack drive in the brick blank cutting machine fundamentally solves the problems of unstable brick blank stacking and easy deviation in traditional designs through high-precision guidance, rigid support, and low-friction movement. Its coordination with components such as photoelectric switches and servo systems further improves the automation level and reliability of the equipment. Eventually, it achieves the comprehensive benefits of neatly stacking brick blanks, increasing efficiency, and reducing the reject rate.

leave a comment