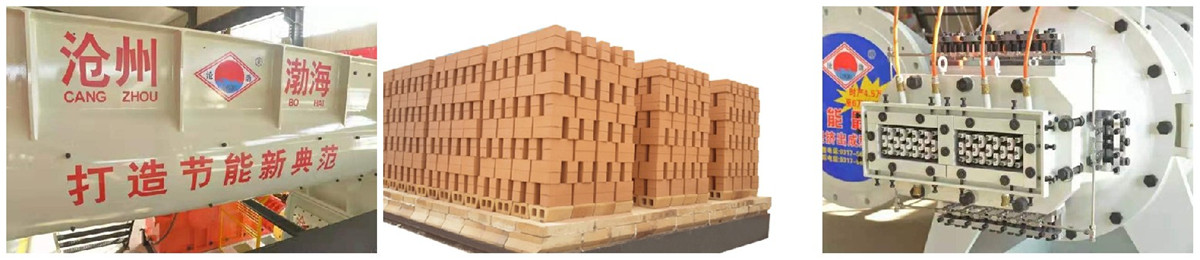

Machine Introduction

The Clay brick Double stage vacuum extruder is a high - performance machine designed for clay brick production. Its double stage structure ensures efficient extrusion. By creating a vacuum environment,

it removes air from the clay, enhancing the density and strength of the bricks. This results in high quality bricks with excellent durability. It's widely used in the construction industry,

helping to produce bricks that meet various building requirements,

and improves production efficiency and product quality.

Product features:

Native extrusion pressure, high vacuum degree, extrusion clay-strip close-grained, neat appearance. Completely for a bit of burning process requirements, high productivity, molding moisture content is low, reduce the energy consumption in the production and the loss. Is the production of the coal gangue, high content fly ash, sand, shale and inferior brick ideal equipment.

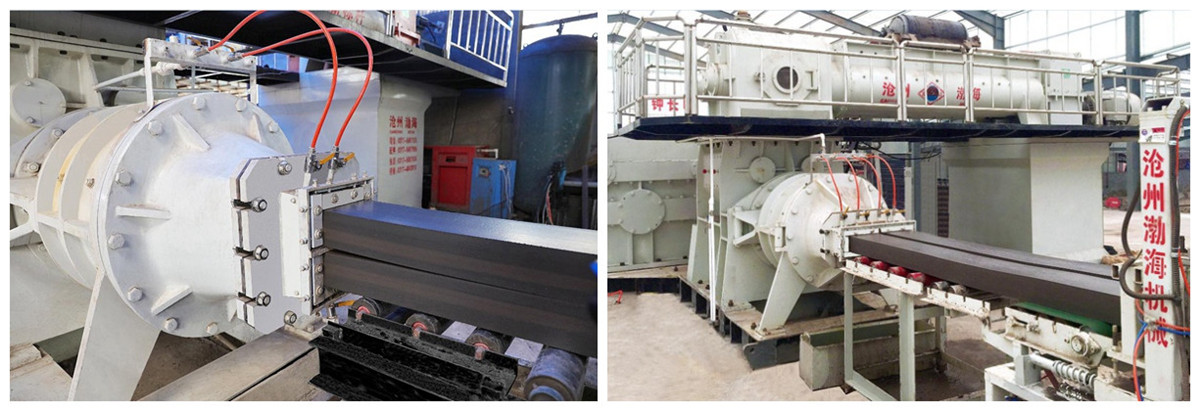

1, vacuum extruder by double mixing extrusion parts (upper) and extrusion molding (lower), and equipped with air compressor system and vacuum system. Adopts pneumatic clutch to implement remote control.

2, vacuum extruder main selection of high qualified steel plate welding and become, with reasonable structure, extrusion pressure, high vacuum degree, strong and durable, strong applicability, low consumption, high efficiency, easy maintenance, etc.

3, vacuum brick machine reamer adopt wear-resisting material, make the life beyond 4 ~ 7 times of the normal reamer; Lead by scientific arrangement (pitch), & other; Micro pressure transmission, high pressure extrusion & throughout; The function, can increase the extrusion pressure and improve the work efficiency; And adopt floating shaft structure, which can eliminate or reduce the spindle caused by the long-term use of bending causes the equipment shook his head, shaking; The device 15 ~ 30% energy saving.

4, vacuum extruder shaft, gear and other important parts adopt high quality carbon steel and alloy steel guitar after conditioning or quenching heat treatment process, extend the service life of the equipment.

5, vacuum extruder dial clay transmission, material level control are equipped with a safety device, the device is not easy to damage the main components in the process of use, and improve the efficiency of the equipment fault maintenance.

6, central vacuum extruder head equipped with a pressure gauge, according to the pressure of the pressure gauge shows the size, can monitor the quality and quantity of products. Raw materials through two-stage extruding and wetting, curing degree and the extrusion pressure is greatly increased. Good quality and high yield.

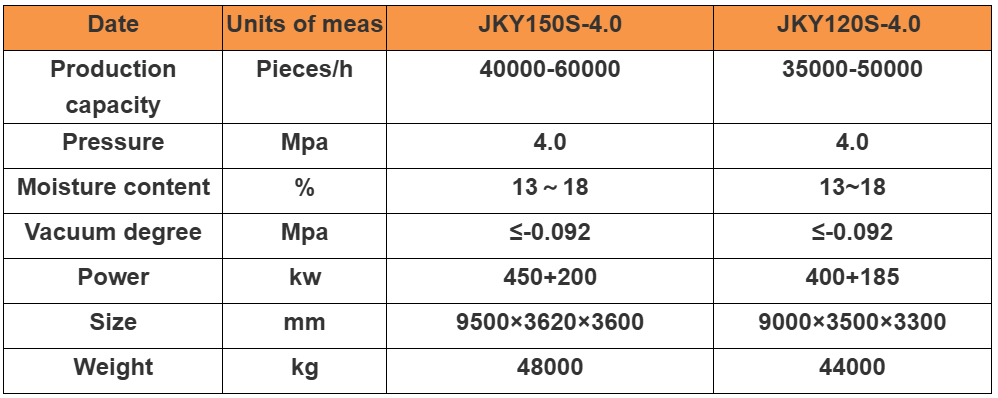

Second, the technical parameters:

Detail Explain:

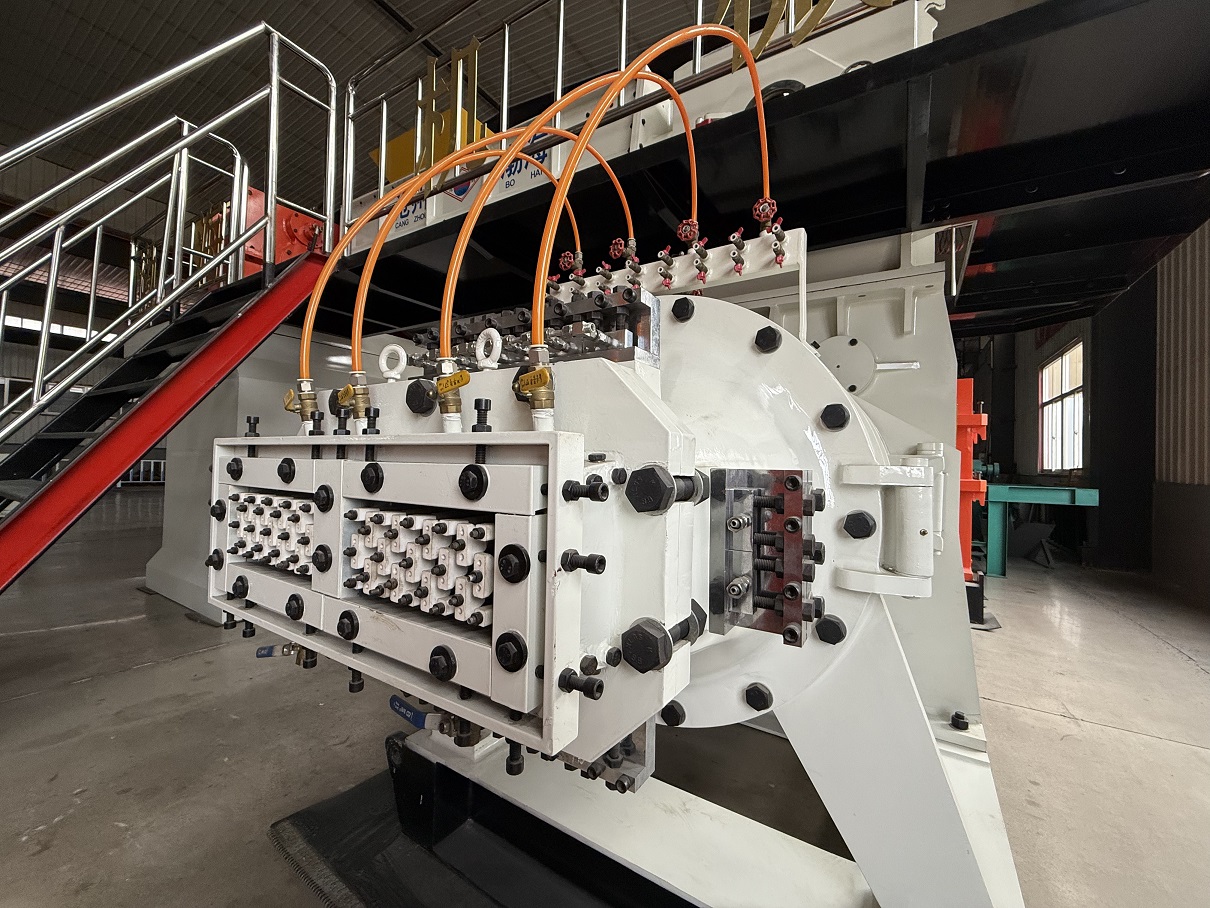

Double ports synchronous output billet, with automatic palletizing system to achieve continuous operation, the output per hour can reach 40,000-60,000 (standard brick), improve efficiency, reduce costs.

The upper ceramic mixing knife adopts the composite process of emery or tungsten carbide ceramic particles and alloy matrix, the surface hardness can reach more than HRC 85, and the wear resistance of traditional alloy cutting tools is increased by 3-5 times, which effectively deals with the wear of hard raw materials such as sand, stone and shale in the process of brick machine mixing. The comprehensive improvement of wear resistance, efficiency and cost is realized in the brick machine mixing process, especially suitable for high load and complex raw material brick making scene.

The main shaft uses 45 steel for tempering treatment to effectively ensure quality. The main shaft design concept is low speed and large torque. The rolling bearing adopts C&U brand bearing, which is first-class in quality and safe and reliable. The main shaft adopts floating shaft design, which prevents the brick machine from shaking its head. It is connected to the jacket shaft, which has strong carrying capacity and keeps the shaft from deformation.

Hard teeth reducer adopts helical gear design and precision machining technology. By optimizing tooth profile parameters and meshing precision, the transmission vibration is effectively reduced, and the running noise is reduced by more than 30%.. After carburizing and quenching treatment of gear surface, the microstructure density of hard gear is better than that of soft gear surface, and the wear amount is reduced by 60%-70% under the same working condition. With the optimization of lubrication system, the gear life can reach 3-5 times of the soft gear reducer.

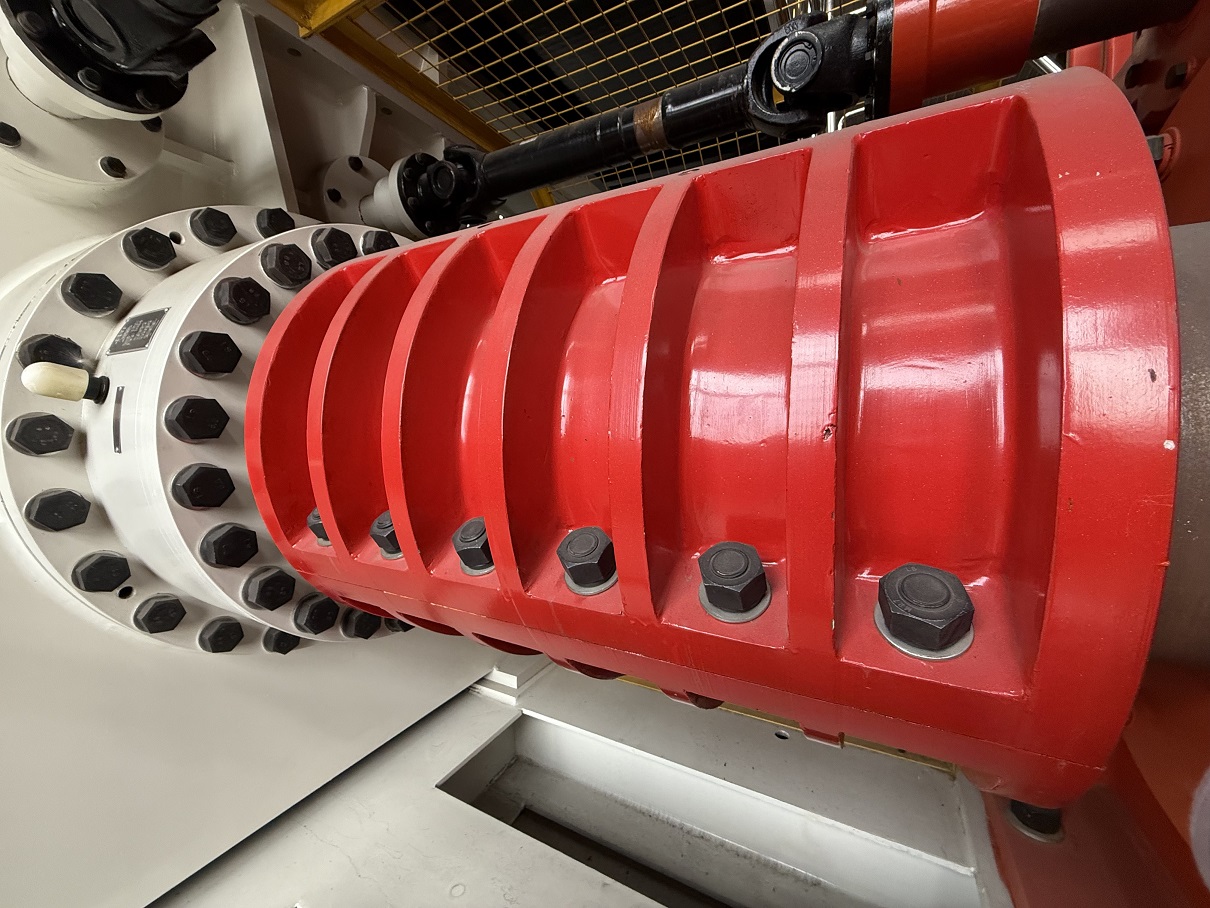

This is the upper stage reducer

Upper stage reducer and lower stage reducer all use hard teeth surface.

The clutch adopts the enhanced pneumatic clutch produced by Wuxi No. 5 Machinery Company. The upper-stage torque is 8,500 N.M, and the lower-stage torque is 20,000 N.M. This clutch could ensure the stability of power transmission during the production process of brick blanks.

The hardness of the high-chromium alloy auger can reach over 62HRC.

Through the synergistic effect of the high hardness body and the carbide strengthening phase, the high chromium alloy auger is 3 to 5 times better than the ordinary cast steel auger in terms of wear resistance, impact resistance and thermal stability.

leave a comment