North Suburb Airport, Cangzhou City, Hebei Province (National Highway 104) cangzhoubohai@gmail.com

Operating Idea

Provide value to users

Operating Idea

Take responsibility for society

Operating Idea

Enable employees to achieve their dreams

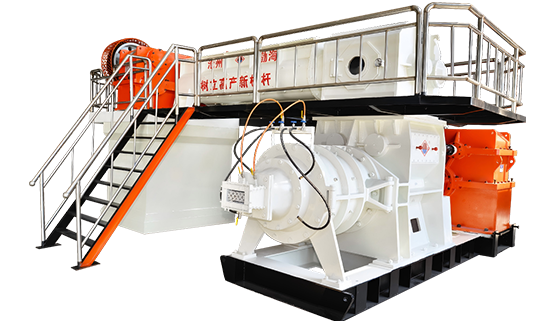

Our products

Recommended products

Bohai Machinery

Bohai of Cangzhou Bohai of the world

Build "No.1 Brand" of the energy-saving, integratedconstruction operating system with top quality and competitiveness.

Enterprise Aim

Frequently Asked Questions?

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqu ad minim veniam, quis nostrud exercitation.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqu ad minim veniam, quis nostrud exercitation.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqu ad minim veniam, quis nostrud exercitation.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqu ad minim veniam, quis nostrud exercitation.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqu ad minim veniam, quis nostrud exercitation.

Latest news are on top